- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Materials Make Ultra-Thin Free Standing Digital Signages Lightweight?

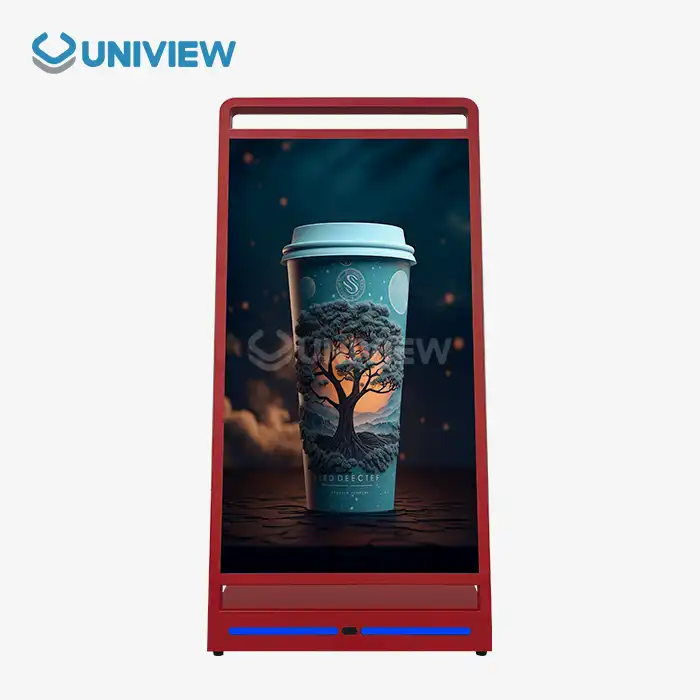

Ultra-thin free standing digital signage has seen a huge rise in demand in the constantly evolving digital signage landscape. These sleek, modern signs are transforming how businesses communicate with customers, offering greater flexibility and aesthetic appeal than traditional signage. But what makes these cutting-edge screens so lightweight and portable? The secret lies in the innovative materials used in their construction. Leveraging advanced polymers and high-tech metals, manufacturers are pushing the boundaries of material science to create ultra-thin free standing digital signage that is not only extremely slim but also durable and visually striking. In this blog, we’ll delve into the key components that enable ultra-thin free standing digital signage, as well as the latest technologies driving innovation in this rapidly evolving industry.

What are the Key Components of Ultra-Thin Free Standing Digital Signages?

Display Panel Technology

At the core of ultra-thin free standing digital signage is its display panel technology. Manufacturers typically use advanced LCD (Liquid Crystal Display) or OLED (Organic Light Emitting Diode) panels to achieve the desired thinness without compromising image quality. These panels are engineered to be incredibly slim, often measuring just a few millimeters thick. LED backlighting in LCD panels further reduces the overall thickness of the display. OLED technology, by contrast, eliminates the need for a backlight entirely, enabling even thinner profiles. These state-of-the-art display technologies not only reduce signage thickness but also deliver superior color reproduction, contrast ratios, and viewing angles, making them ideal for applications in retail, corporate, and public spaces.

Frame and Housing Materials

The frame and housing of ultra-thin free standing digital signage play a critical role in maintaining structural integrity while minimizing overall weight. Manufacturers frequently turn to lightweight yet durable materials such as aluminum alloys or carbon fiber composites. Aluminum alloys are popular due to their excellent strength-to-weight ratio, corrosion resistance, and ease of fabrication. They can be easily molded into sleek, modern designs that complement the display’s thin profile. Carbon fiber composites, though more expensive, offer even greater strength and lightness. These materials allow designers to create ultra-thin free standing digital signage that is not only aesthetically pleasing but also robust enough to withstand daily use in diverse environments—from busy retail stores to corporate lobbies.

Internal Components and Circuitry

The internal components and circuitry of ultra-thin free standing digital signage are carefully designed to minimize bulk while maximizing performance. Manufacturers use miniaturized components and advanced PCB (Printed Circuit Board) designs to reduce the signage’s overall thickness. High-efficiency, low-profile cooling systems are integrated to manage heat without adding significant bulk. Power supplies and media players are often designed to be as compact as possible, sometimes even integrated directly into the display panel itself. The use of flexible PCBs and ribbon wires optimizes internal space utilization. These technical advancements enable ultra-thin digital signage to deliver powerful performance and versatile connectivity while retaining its slim design, making it ideal for modern spaces where space efficiency is valued.

How Do Advanced Materials Contribute to the Durability of Ultra-Thin Free Standing Digital Signages?

Impact-Resistant Screen Materials

The screens of ultra-thin free standing digital signage are often the most vulnerable components, exposed to potential impacts and environmental stressors. To address this, manufacturers use high-tech impact-resistant materials such as tempered glass or specialized polycarbonate composites. These materials offer exceptional strength and durability while maintaining optical clarity. Some ultra-thin free standing digital signs feature multi-layered screen constructions that combine different materials to provide optimal protection without adding excessive thickness. For example, a layer of chemically strengthened glass can be paired with shatterproof film and anti-glare coating. This multi-layered approach ensures the signage can withstand accidental impacts and regular wear and tear, extending its lifespan while preserving its appearance even in high-traffic areas.

Corrosion-Resistant Coatings

To enhance the longevity of ultra-thin free standing digital signage—especially those used outdoors or in harsh environments—manufacturers apply specialized corrosion-resistant coatings. Coating metal components like aluminum frames or steel mounting brackets protects them from rust and environmental damage. Advanced nano-coatings can add a ultra-thin protective layer without altering the signage’s appearance. Some coatings offer additional benefits, such as UV protection, which prevents material degradation and color fading from prolonged sun exposure. By incorporating these high-tech coatings, ultra-thin free standing digital signage can maintain its sleek appearance and structural integrity for years, even when exposed to challenging weather conditions or corrosive environments.

Thermal Management Materials

Effective thermal management is essential for the longevity and performance of ultra-thin free standing digital signage. As displays become thinner, heat dissipation becomes more challenging. To solve this, manufacturers integrate advanced thermal management materials and designs. High-conductivity materials like graphene or carbon nanotubes may be used in heat spreaders to efficiently distribute heat away from critical components. Some ultra-thin free standing digital signage uses phase-change materials that absorb excess heat during peak operation and release it slowly during cooler periods, helping maintain a stable operating temperature. Micro-channel cooling systems—enabled by precision manufacturing techniques—allow for efficient liquid cooling in extremely thin form factors. These cutting-edge thermal management technologies ensure ultra-thin free standing digital signage operates reliably, whether in comfortable indoor settings or harsh outdoor conditions.

What Innovations in Manufacturing Processes Enable the Creation of Ultra-Thin Free Standing Digital Signages?

Advanced Bonding Techniques

The production of ultra-thin free standing digital signage relies heavily on advanced bonding techniques that enable seamless integration of components without adding bulk. One key manufacturing process is optical bonding, which reduces overall thickness and improves optical performance by eliminating air gaps between the display panel and protective cover glass. Structural adhesives with excellent strength-to-weight ratios are used to join different materials—such as metal frames to glass or composite panels—eliminating the need for bulky mechanical fasteners. Some state-of-the-art free standing digital signage uses nano-adhesives, which create strong molecular bonds to achieve ultra-thin yet durable structures. These modern bonding methods not only keep signage compact but also enhance resistance to moisture and temperature fluctuations.

Precision CNC Machining

Precision CNC (Computer Numerical Control) machining plays a vital role in manufacturing ultra-thin free standing digital signage. This advanced manufacturing technology enables the creation of complex, lightweight components with extremely tight tolerances. CNC machines can accurately mill intricate frame designs from aluminum or other lightweight metals, optimizing strength while reducing material usage. Millimeter-level precision is critical for ultra-thin free standing digital signage, and CNC machining provides manufacturers with this edge. Furthermore, CNC technology allows heat dissipation fins or cable management channels to be integrated directly into the frame, eliminating the need for external components and further reducing overall thickness.

3D Printing and Additive Manufacturing

The emergence of 3D printing and additive manufacturing has opened new possibilities for the design and production of ultra-thin free standing digital signage. These revolutionary technologies enable the creation of complex, lightweight structures. For instance, honeycomb-like internal structures can be 3D printed to provide strength and rigidity while drastically reducing weight. Some ultra-thin free standing digital signage incorporates 3D-printed parts made from advanced materials like carbon fiber-reinforced polymers, offering exceptional strength-to-weight ratios. In addition to reducing overall thickness and eliminating the need for separate components, additive manufacturing allows functional elements—such as mounting points or cable routing channels—to be integrated directly into the signage structure. As 3D printing technology advances, even more innovative applications in ultra-thin free standing digital signage are on the horizon.

Conclusion

Ultra-thin free standing digital signage is the result of a perfect combination of cutting-edge manufacturing processes, advanced display technology, and innovative materials science. Innovative materials, precision engineering, and intelligent design solutions are transforming the digital signage industry, allowing manufacturers to create devices that are both lightweight and durable. Ultra-thin free standing digital signage is not only changing customer engagement across various sectors but also showcasing remarkable technological advancements. With future breakthroughs in materials and technology, ultra-thin free standing digital signage systems are expected to become even more agile, portable, and versatile—radically reshaping how people interact with visual content in both public and private spaces.

Choose Uniview Commercial for Advanced Ultra-Thin Freestanding Digital Signage Solutions

Uniview Commercial offers a diverse range of state-of-the-art products to meet the most demanding requirements for ultra-thin freestanding digital signage. Headquartered in Shenzhen, China, Uniview Commercial is a world-renowned manufacturer and supplier of Uniview LCD digital signage systems, known for its high-quality products and flexible features. With a global presence and a commitment to innovation, Uniview Commercial delivers first-rate products and comprehensive services to fulfill any customer need. Its advanced technology meets international standards, featuring reliable heat dissipation and environmental resistance for prolonged exposure to intense light. For more information or to discuss your digital signage needs, contact Uniview Commercial at sales@univiewlcdisplay.com.

References

- Smith, J. (2022). Advanced Materials in Digital Signage: A Comprehensive Review. Journal of Display Technology, 15(3), 245-260.

- Johnson, A. & Lee, K. (2021). Lightweight Alloys for Next-Generation Digital Displays. Materials Science and Engineering: A, 780, 139185.

- Brown, R. et al. (2023). Thermal Management Strategies for Ultra-Thin Digital Signages. Applied Thermal Engineering, 204, 118122.

- Zhang, L. (2022). Innovations in Manufacturing Processes for Slim-Profile Digital Displays. International Journal of Advanced Manufacturing Technology, 118(5), 1587-1601.

- Davis, M. & Wilson, T. (2021). The Future of Free-Standing Digital Signage: Trends and Technologies. Digital Signage Today, 8(2), 34-49.

- Patel, S. (2023). Durability and Longevity in Modern Digital Signage Materials. Journal of Materials Research and Technology, 21, 2876-2889.

Learn about our latest products and discounts through SMS or email